Technical Transportation of Hazardous Materials

The transportation of hazardous materials is not just about slapping a placard on the side of the truck. The transportation of hazardous materials requires that one be well versed in the governing national and international regulations as well as have in-depth knowledge of the nine classes of hazardous materials. Other required knowledge areas include compatibility of classes, shipping documents, marking, labeling, packaging, placarding and emergency response information. These are fundamental to managing the transportation of hazardous materials but much more will be needed if a planner or manager chooses to also certify hazardous materials for transportation. Let’s discuss a few of these topics and find out why planning for the transportation of hazardous materials is not as simple as commonly thought. I will delve into compatibility requirements later. It’s important to understand the table thoroughly before diving into the advanced stuff as it’s easy to become overwhelmed with the sheer amount of data provided in the regulatory materials.

Hazardous materials are defined as “a substance or material, including a hazardous substance, which has been determined by the Secretary of Transportation to be capable of posing an unreasonable risk to health, safety or property when transported in commerce, and which has been so designated.” The classes of hazardous materials are as follows: 1) Explosives, 2) Gases, 3) Flammable Liquids, 4) Flammable Solids, Spontaneously Combustible & Dangerous when wet, 5) Oxidizer and Organic peroxide, 6) Toxic Substances and Infectious Substances, 7) Radioactive, 8) Corrosive, 9) Miscellaneous. These primary classes are further subdivided into divisions that specify the hazard of each class.

Class 1 Explosives

Division 1.1: Mass Explosive Hazard

Division 1.2 Projection Hazard

Division 1.3 Fire and/or Minor Blast Hazard

Division 1.4 Minor Explosion Hazard

Division 1.5 Very Insensitive with Mass Explosion Hazard

Division 1.6 Extremely Insensitive; No Mass Explosion Hazard

Class 2 Gases

Division 2.1 Flammable Gases

Division 2.2 Nonflammable Gases

Division 2.3 Toxic Gases

Class 3 Flammable Liquids

Division 3.1 All Flammable Liquids

Division 3.2 All Combustible Liquids

Class 4 Flammable Solids

Division 4.1 Flammable Solids

Division 4.2 Spontaneously Combustible

Division 4.3 Dangerous when wet

Class 5 Oxidizing Substances and Infectious Substances

Division 5.1 Oxidizing Substances

Division 5.2 Organic Peroxides

Class 6 Toxic Substances and Infectious Substances

Division 6.1 Toxic Substances

Division 6.2 Infectious Substances

Class 7 Radioactive Material

Class 8 Corrosive

Class 9 Miscellaneous Hazardous Materials

Guidance governing the transportation of hazardous materials in the United States is found primarily in 49 CFR or the 49 Code of Federal Regulations (CFR) Subchapter C. The Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) regulates the transport of hazardous materials through the use of 49 CFR, Subchapter C.

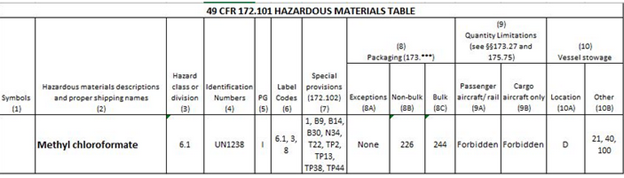

Part 172.101 of subchapter C includes the Hazardous Materials Table which is the principle means for researching special requirements for all hazardous materials. This should be the first area of endeavor for anyone wishing to gain a better understanding of hazardous material classifications and their special provisions. A thorough understanding of how to decipher the displayed information is critical for planners and transporters as this table is a central part of the research process.

The hazardous materials table identifies the hazard class of each identified element, provides the proper shipping name(s), as well as to specify labeling and packaging requirements for the mode of transportation to be utilized. Quantity limitations and vessel stowage requirements are also displayed in the table’s 9th and 10th columns.

If we look at one element from the table we can determine the following information for the element Methyl Chloroformate.

1. Methyl chloroformate is the proper shipping name

2. Methyl chloroformate is classified as a toxic substance

3. It has a UN number of 1238, the international packaging code

4. It has a packing group class of “I” this packing group indicates “great” danger

5. The label codes are 6.1, 3 and 8 meaning, these three distinctive labels and placards should be used to identify this element for all transport.

6. Multiple special provisions govern this element:

a. 1: the material is poisonous by inhalation

b. B9: bottom outlets are not authorized for packaging

c. B14: Bulk packaging must be insulated

d. B30: DOT 412, DOT 51 portable tanks must be made of stainless steel. Thickness of stainless steel must be greater than 7.62mm or the thickness required for a tank with a design pressure at least equal to 1.5 times the vapor pressure of the lading at 46 degrees Celsius.

e. N34: Aluminum construction materials are not authorized for any part of a packaging which is normally in contact with the hazardous material.

f. T22: For portable tanks, the organic liquid must have a flash point above 50 degrees Celsius.

g. TP2: The maximum degree of filling must not exceed the degree of filling determined by the applicable formula established in 49 CFR.

h. TP13: self-contained breathing apparatus must be provided when this hazardous material is transported by sea.

i. TP38: Each portable tank must be insulated with an insulating material so that the overall thermal conductance at 15.5 degrees Celsius is no more than 1.5333 kilojoules per hour per square meter degree Celsius temperature differential.

j. TP44: Each portable tank must be made of stainless steel, except that steel other than stainless steel may be used in accordance with the provisions of part 173.24b of subchapter C.

7. Packaging has three provisions; 1) exceptions, 2) non-bulk, and 3) bulk. For this material there are no packaging exceptions, non-bulk packaging is not authorized but with an exception of “226”, reference 49CFR 173.226, bulk packaging has an exception for “244”, reference 49CFR 173.244.

8. In column 9; quantity limitations we learn that this material is not authorized transport via passenger aircraft or cargo aircraft.

9. In column 10; vessel stowage, has two parts, for location, designation of “D” means that this material may be stowed on a deck only on cargo vessels or on a passenger vessel carrying a number of passengers limited to 25. Other vessel stowage restrictions listed: 21: segregation same as for flammable liquids, 40: stow “clear of living quarters”, 100: stow away from flammable solids.

As you can see, the requirements and restrictions for transporting hazardous materials are at times daunting, I chose a material with more restrictions than most to demonstrate just how restrictive 49CFR can be. This also demonstrates just how much research, cross referencing and attention to detail is needed to adequately plan for the transportation of hazardous materials.

During the course of your research, you will certainly be required to reference other regulatory materials, guidebooks and instructions. Other important regulatory guidance relating to the transportation of hazardous materials can be found with these organizations and corresponding publications:

· IATA – International Air Transport Association; DGR: Dangerous Goods Regulations

· IMO – International Maritime Organization; IMDG: International Maritime Dangerous Goods code

· ICAO – International Civil Aviation Organization; Technical Instructions for HAZMAT

· AFMAN 24-204 – US Air Force Manual, Preparing HAZMAT fir military air shipments

Another important publication to understand and reference is the ERG: Emergency Response Guidebook. This publication commonly referred to as the “orange book” is the guidebook used by first responders for hazardous material transportation accidents or incidents that occur. This publication is provided by the US Department of Transportation and commonly referenced throughout North America to include Canada and Mexico. The sections are color coded for speed in referencing, the orange section contains 62 response guides that list detailed safety procedures.

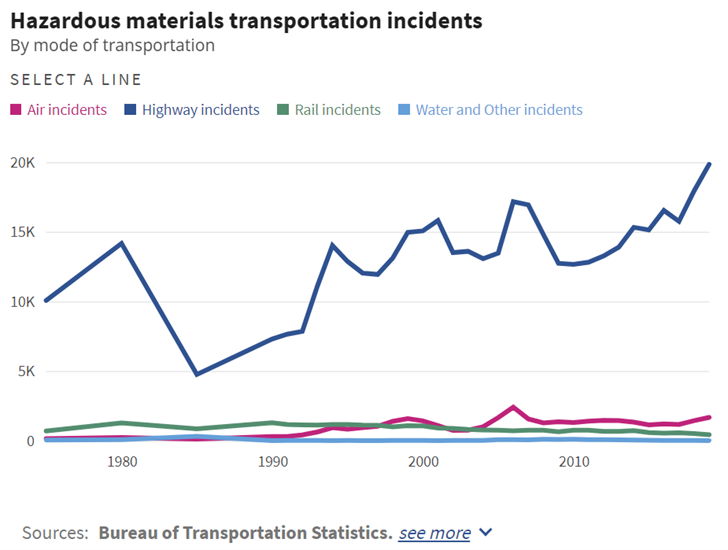

Unfortunately, hazardous material related transportation incidents are on the rise and have been for decades. As you can see, highway incidents are climbing significantly while the other modes of transportation have plateaued. Obviously the sheer volume of cargo transportation by highway has risen dramatically over the past 15 years, so that may account for the precipitous climb since 2010. The fact remains that more hazardous material transportation incidents are occurring, hence the reason for understanding the hazards and taking preventative steps to mitigate or reduce the prevalence of incidents. Follow up posts will cover compatibility requirements, packaging, labeling, placarding and handling.